WHAT THE SOFTWARE DOES

EXAMPLE BENEFITS

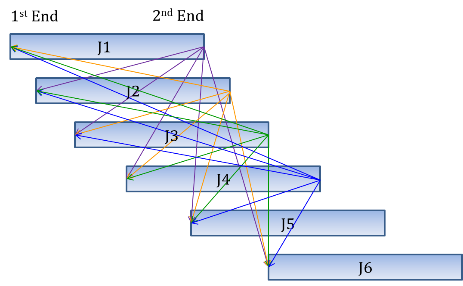

ITERATION PROCESS

First End-To-First End

Second End-To-Secont End

First End-To-Secont End

Second End-To-First End

| Calculates the maximum, minimum, and average hi-lo, CL eccentricity, and SCF | |

| (stress concentration factor) and identifies the corresponding joints | ||

| Selects a subset of any desired number of pipe joints that result in the best SCF | |

| Calculates the maximum, minimum, and average hi-lo, CL eccentricity, and SCF of the | |

| selected subset and identifies the corresponding joints | ||

| Considers any random joint, any end (to be) welded to any random joint, any end, | |

| based on either the OD or ID and on any desired SCF formula | ||

| Example, No. of iterations to determine the hi-lo, eccentricity, and SCF |

| 100 joints: ~40,000 | |

| 500 joints: ~1,000,000 |

| Example, No. of iterations to select half of the pipe joints with the best SCF |

| Selecting 50 of 100 joints: ~310,000 | |

| Selecting 250 of 500 joints: ~35,000,000 |

| It is nearly impossible to perform this analysis using spreadsheets |

EXAMPLE BENEFITS

| Verifying that the maximum calculated SCR doesn't exceed the SCF assumed in the | |

| design | ||

| Determining the additional margin on fatigue life (if any as per the calculated SCF) | |

| Determining whether machining of the pipe ends is required--eliminating machining |

| Saves cost | |

| Saves time | |

| Prevents loss of wall thickness (detrimental for strength and ECA in particular) | |

| Eliminates the risk of potential crack starters |

| Selecting the best joints to send offshore for installation while keeping the rest | |

| onshore for spares (such as a spare riser) | ||

| Eliminating the logistics, cost, likely errors, and time of |

| Pipe joint sorting (certain joints in sequence) | |

| End matching (rotating the joints for best fit) |

| Selecting the best joints (groups) to put in the high fatigue zones such as the riser | |

| sagbend, hang off, and hog bend |

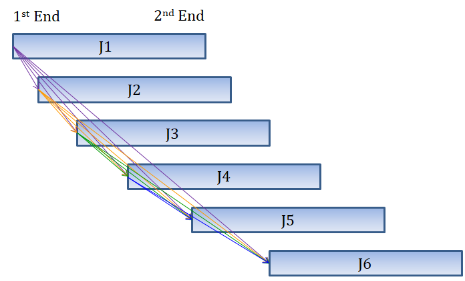

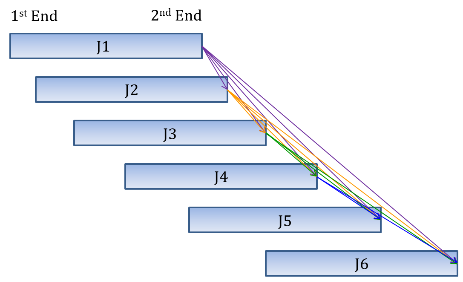

ITERATION PROCESS

First End-To-First End

Second End-To-Secont End

First End-To-Secont End

Second End-To-First End

Page Title

ARTIFEX ENGINEERING INC. OFFERS A PIPE JOINT MANAGEMENT SOFTWARE (PJMS)

SOFTWARE